The group can rely on the following facilities for morphological, thermal, and structural characterization of materials:

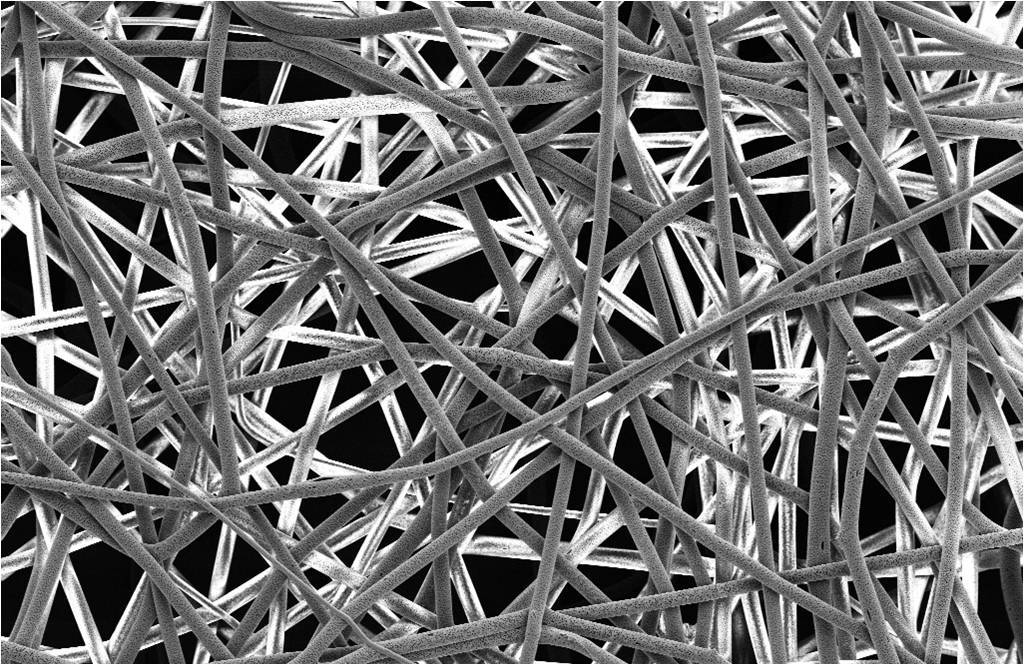

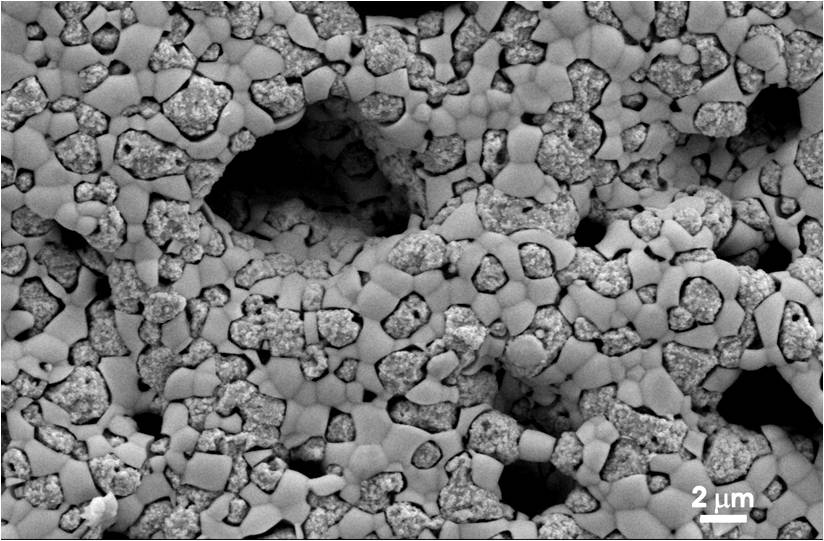

Morphological characterization is performed using a Field Emission Scanning Electron Microscope (FE-SEM) SUPRA™ 35 (Carl Zeiss SMT, Oberkochen, Germany), which enables high-resolution imaging of surface morphology and microstructure, as well as elemental analysis via EDS.

Thermal analysis is conducted using a Mettler Toledo system combining Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), allowing precise evaluation of thermal stability, decomposition behavior, and phase transitions.

Specific surface area and porosity are measured using a Micromeritics BET system, providing detailed information on surface area, pore size distribution, and total pore volume.

Structural characterization is carried out using a Philips PANalytical X’Pert Pro X-ray Diffractometer (XRD), suitable for phase identification, crystallinity analysis, and determination of lattice parameters.